Additive vs Subtractive Manufacturing: A Comparison

In the world of manufacturing, there are two main methods that reign supreme: additive and subtractive manufacturing. Now, you might be wondering, what’s the big difference between the two? Well, let me break it down for you!

Additive manufacturing, also known as 3D printing, is all about building things layer by layer. It’s like creating a masterpiece one brushstroke at a time. With additive manufacturing, you start with nothing and gradually add material to form the final product. It’s like magic happening right before your eyes!

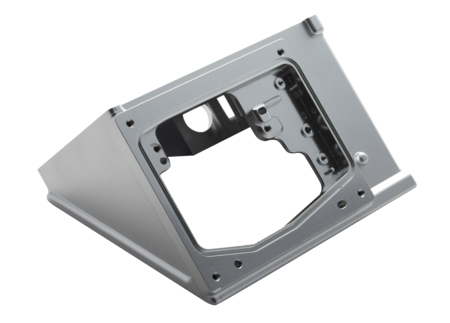

On the other hand, subtractive manufacturing is more like sculpting. You start with a block of material and carefully chip away at it until you get the desired shape. It’s a bit like carving a statue out of stone – slow and steady wins the race.

Now, when it comes to choosing between additive and subtractive manufacturing, it really depends on what you’re looking to create. Additive manufacturing is great for complex designs with intricate details, while subtractive manufacturing is perfect for creating sturdy and durable prototypes.

In the end, both methods have their own strengths and weaknesses. Additive manufacturing is fast and flexible, but it can be costly. Subtractive manufacturing, on the other hand, is precise and reliable, but it can take longer to produce parts.

So, whether you’re team additive or team subtractive, it’s important to understand the unique features of each method and choose the one that best suits your project. After all, in the world of manufacturing, it’s all about finding the perfect balance between creativity and practicality.